What does PUWER cover?

The Regulations apply to all workplaces and work situations where the HSW Act applies and deals with work equipment and machinery used every day in workplaces, including factories, offices, shops, hospitals, construction sites, farms – wherever equipment and machinery is used at work.

What is the aim of PUWER?

The Regulations aim to make working life safer for everyone using and coming into contact with equipment: employers and employees, contractors, suppliers, and others.

What do I gain from knowing if I comply with the PUWER Regulations?

"Hello,

My name is Phil and I am a GO.tago practitioner so let me explain what we can do for you.

First and foremost, if you have fallen short of the outcome of a Safety Inspection, give us a call for an immediate resolution. We will provide confirmation for you to presetn to the inspector that improvement work is in progress. We will work with you on the smallest matter to provide a satisfactory outcome.

To obtain a PUWER Compliance certificate, simply follow these two steps:

1. Obtain a one-day GAP Analysis. This is a snapshot of where you are, and where you need to go. If you fully comply, we will provide a certificate. If we can suggest improvements, we will tell you. Remember, we are working for you, not the Health and Safety Executive.

2. Fill the GAPS. A simple ongoing bespoke arrangement for advice and guidance,. This can often be integrated into an ISO 45001 support commitment if you are already certified. If not, see our OHAS page

Peace of mind. You will also gain from knowing the culture of your business is being reflected in productivity, profitability, and where applicable, employee participation.

If you operate machinery or work equipment, allowing your business to be governed by these regulations will facilitate the important overlap to all other aspects of health and safety and allow your business to grow.

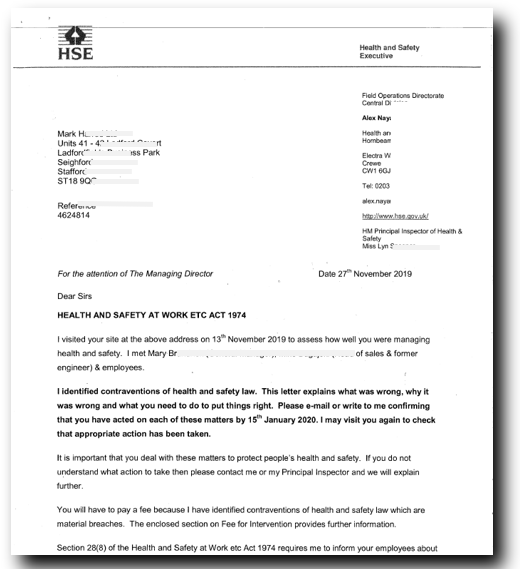

What happens if I am not compliant ?

The Health and Safety Executive (UK Government) can visit any time, and moreover if there has been a reportable hazardous event. Material breaches - Notification of Contravention will be issued, with time limits and fines. Prohibition notices can also include the cessation of business activities, and court action.

How can we help you?

What is PUWER and who does it apply to?

The Provision and Use of Work Equipment Regulations 1998

(The Regulations), commonly known as PUWER, place duties on people and companies who own, operate or have control over work equipment. PUWER also places responsibilities on businesses and organisations whose employees use work equipment, whether owned by them or not.

Special Note for SME's on ISO 45001.

You’re not required by law to implement ISO 45001 or other similar management standards, but they can help provide a structured framework for ensuring a safe and healthy workplace. In some respects, ISO 45001 goes beyond what the law requires, so consider carefully whether to adopt it. If your organisation is small or low-risk, a simpler and less bureaucratic approach may be more appropriate such as that outlined in

HSE’s guidance on health and safety made simple.

Speak to your GO.tago Practitioner